Exclusive First Look at Davie/Helsinki Shipyard's Arctic Security Cutter Design

More specifics on the Multi-Purpose Polar Support Ship

(Note: This is another article that is too long for an e-mail message. Be sure to click on the link in order to read to the finish.)

In late May, Davie/Helsinki Shipyard unveiled their Multi-Purpose Polar Support Ship (MPPS) at CANSEC, a Canadian defense trade show. I wrote about it in the article Analyzing the Arctic Security Cutter Request for Information based on some initial information.

The MPPS is a fourth-generation design (updated for the U.S. Coast Guard) that traces its roots back to the FESCO Sakhalin, sometimes called “The Father of Modern Icebreakers.” We’ll get the design history later. But first, an update courtesy of Davie Defense, Davie’s new U.S. subsidiary1.

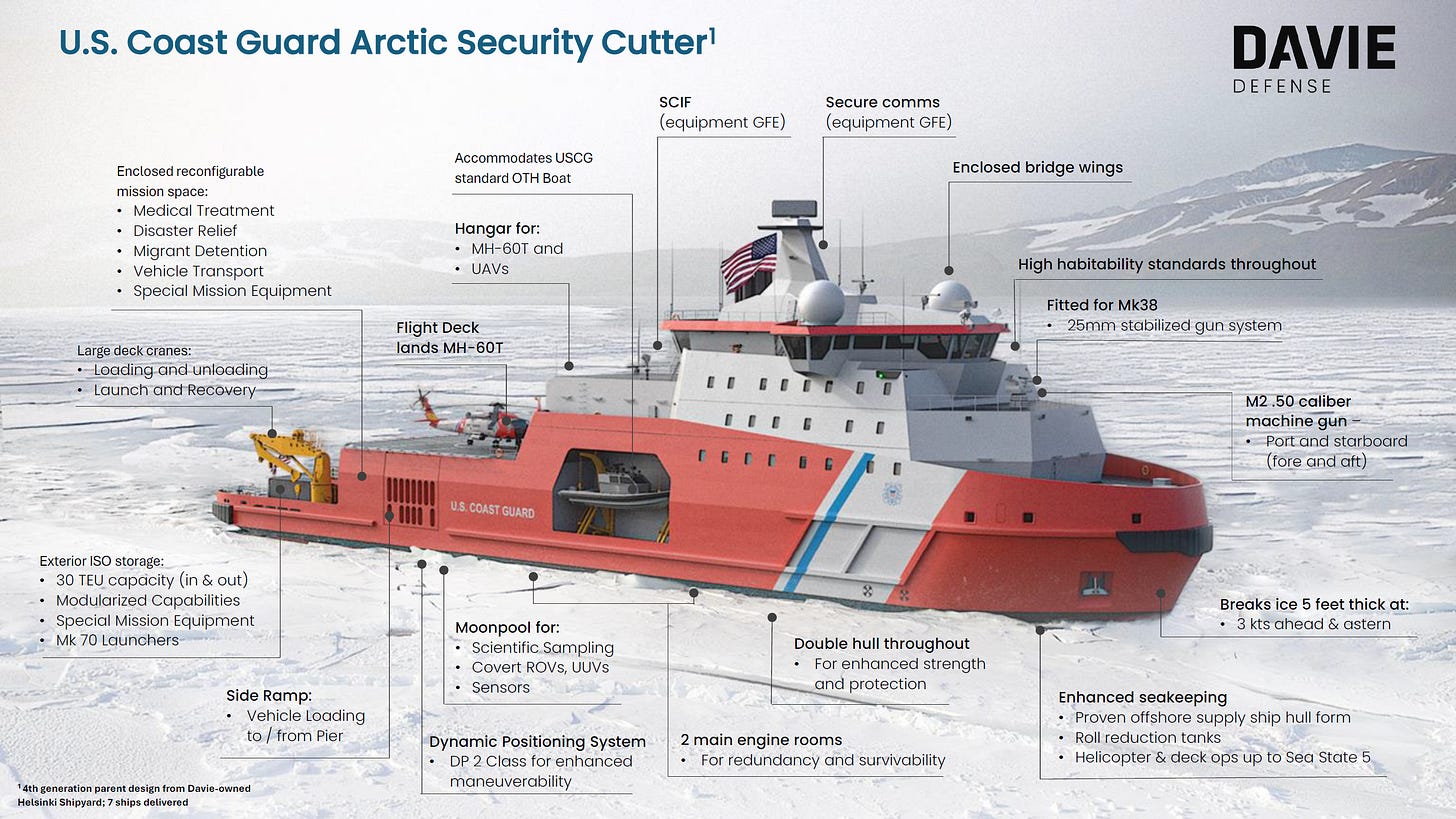

Davie/Helsinki Shipyard’s Arctic Security Cutter Design

Mast and equipment rooms for sensors, comms and combat systems

Accommodation for crew of 124 with 90 days endurance

Large covered mission deck for modular payloads

Up to 30 TEU or ground vehicles

Underwater/surface/air vehicles

Moonpool for underwater missions

Built in survivability due to double hull, fully duplicated power generation, distribution and propulsion

Two fully redundant engine rooms

Reserve power for mission needs and future growth

Option for underwater silencing

25 mm Mk38 deck gun (upgradable to 57mm)

Machine guns or remote weapon stations

Helicopter deck and hangar for MH-60 Jayhawk

Roll reduction tank for enhanced seakeeping

Option for Mk70 vertical launchers for US Navy Standard missiles

Available for delivery from Helsinki Shipyard in 26 months from contract award.

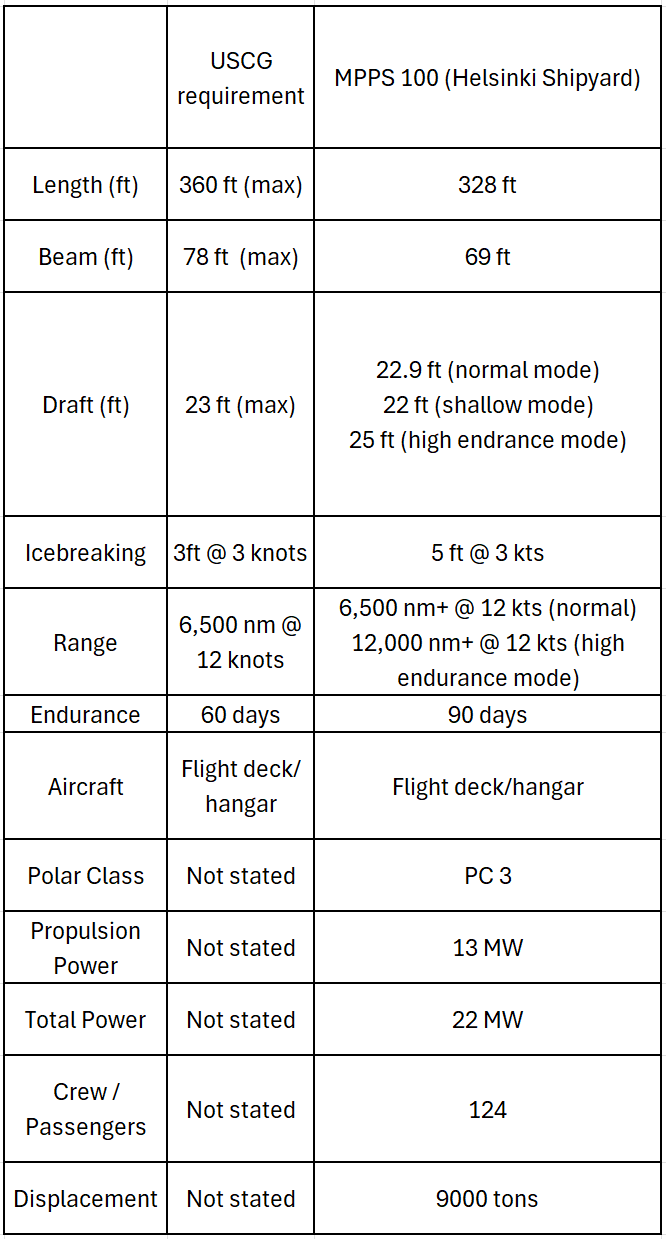

Meets U.S. Coast Guard’s Preliminary Requirements:

U.S. Coast Guard Concerns Not Listed in the RFI

These are the same concerns I wrote about in last week’s article analyzing the Multi-Purpose Icebreaker (MPI) design.

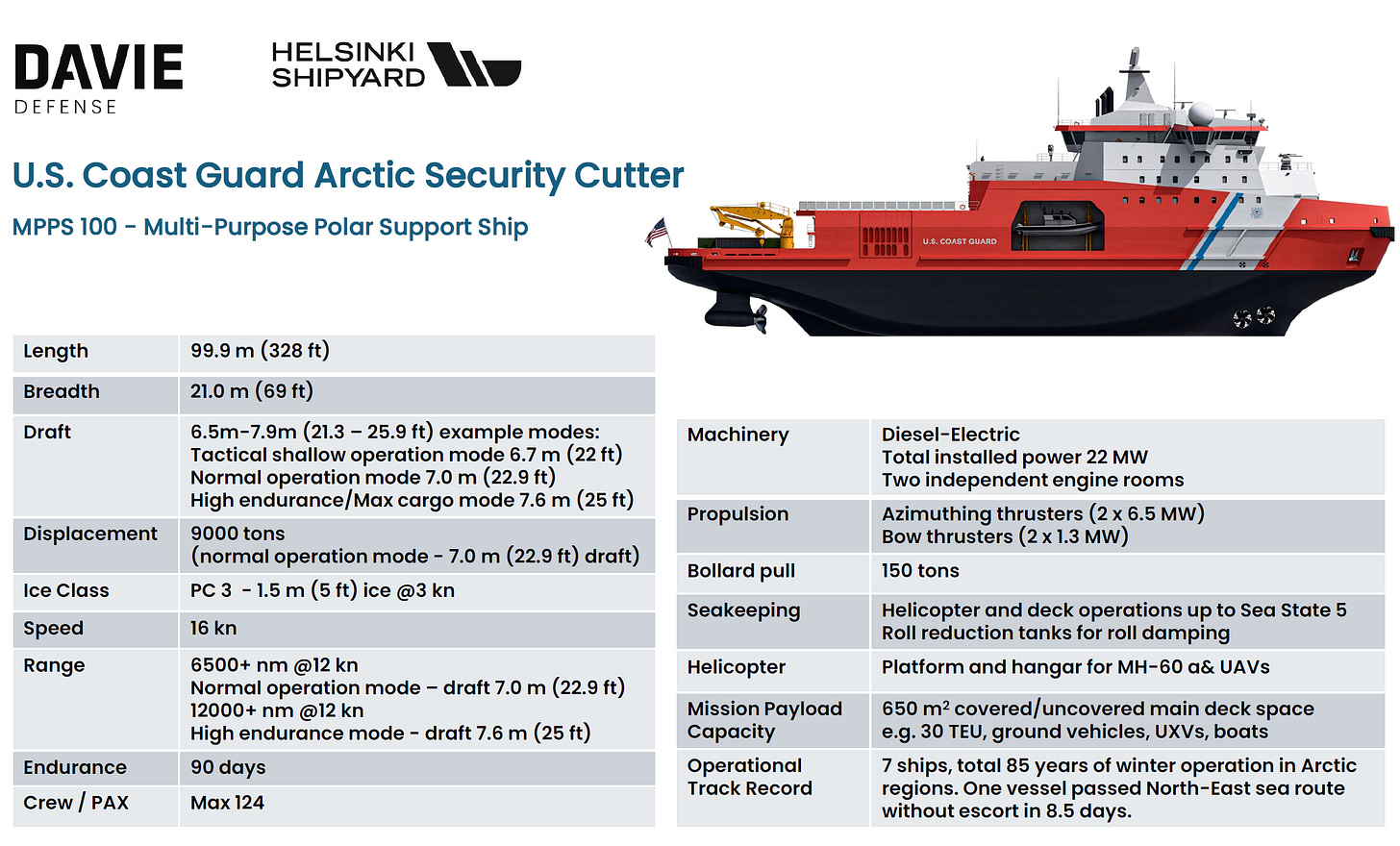

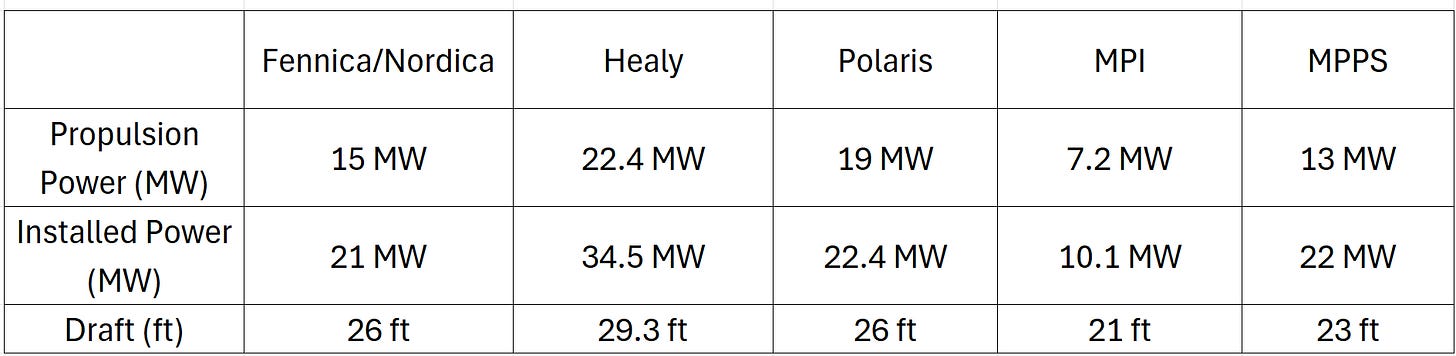

Propulsion Power:

The propulsion power of the MPPS is more in line with other medium icebreakers, noting that the RFI states a maximum draft of 23ft. As mentioned last week, shallow drafts limit power by reducing the maximum diameter of the propeller and limiting the size of components.

Redundant Power:

The MPPS has a good amount of reserve power for redundancy and to support future growth. Although we don’t yet know the size and number of diesel engines, it should be safe to assume that it will be similar to the most recent vessel of this type, NB 514, which has 4 diesels of the same size. For the MPPS, that would equate to 4 x 5.5 MW diesels generators. With one unavailable, the ship could still generate 16.5 MW- enough for pull propulsion power plus 3.5 MW.

Survivability/Crew Size:

As a special purpose ship with more than sixty but less than 240 persons, the vessel has to meet a higher level of safety and stability requirements than a cargo ship. These SPS requirements are essentially equivalent to a passenger ship with less than 36 passengers.

- Safe Return to Port (SRTP) review

In the past, I’ve used the SRTP classification as a shorthand for redundancy, as it requires key components to be located within different fire/flooding boundaries2. As I wrote in a previous article:

Certain large passenger ships built on or after July 1, 2010 have to comply with the SOLAS Safe Return to Port (SRTP) requirement. This means that a ship must be capable of losing a space (up to the applicable boundary) due to fire or flooding and be able to maintain essential services. For the case of fire, it must be able to safely return to port under its own power while maintaining essential services.

A reader pointed out to me that the purpose of SRTP is for a ship to serve as its own lifeboat, an important consideration as cruise ships grow larger and evacuation becomes more difficult. The IMO describes it this way:

In this regard, the MSC [Maritime Safety Committee, which developed the rules] agreed that the best way to avoid having thousands of persons in survival craft was to ensure that future passenger ships were robustly designed so that, after a casualty, the passengers and crew would normally be able to evacuate to a safe area on board as the ship proceeds back to port under its own power.

“Safe area” has a particular meaning- a place within the vessel where passengers can live until the ship returns to port or rescue arrives.

In summary, SRTP requires two things: a design for redundancy with key components placed in separate fire/flood zones, and a passenger ‘safe area’ which receives a required level of “hotel” services.

- MPPS: Redundant

The MPPS meets the first criteria, as it has two separate engine rooms separated forward/aft by fire and flood boundaries. This is a design feature not found on the vast majority of commercial vessels.

The MPPS does not meet the second criteria as currently designed as it lacks the redundancy for the hotel services required to support a safe area. For that reason, it does not meet the SRTP criteria. This is less of a consideration for warships, but if SRTP is required, this can be modified.

The MPPS also features a double hull.

- Accommodation

Accommodation for up to 124 should be sufficient for the U.S. Coast Guard’s needs.

Weapons and Sensors:

As noted above, the MPPS has the necessary space for sensors, communications, and combat systems. For weapons, the design currently features:

1 x Mk 38 25mm deck gun (can be modified for 57mm)

4 x M2 .50cal mounts/remote weapons stations

Containerized mission payloads for ISR, ASW, mine laying and other missions, such as Mk70 vertical launchers (one Mk70 contains four VLS cells) or the SUMICO mine laying system.

Reserve power for future growth

For sensors:

Mast and equipment rooms for sensors, comms and combat systems

Moon pool to deploy Remotely Operated Vehicles (ROVs) or Unmanned Underwater Vehicles (UUVs)

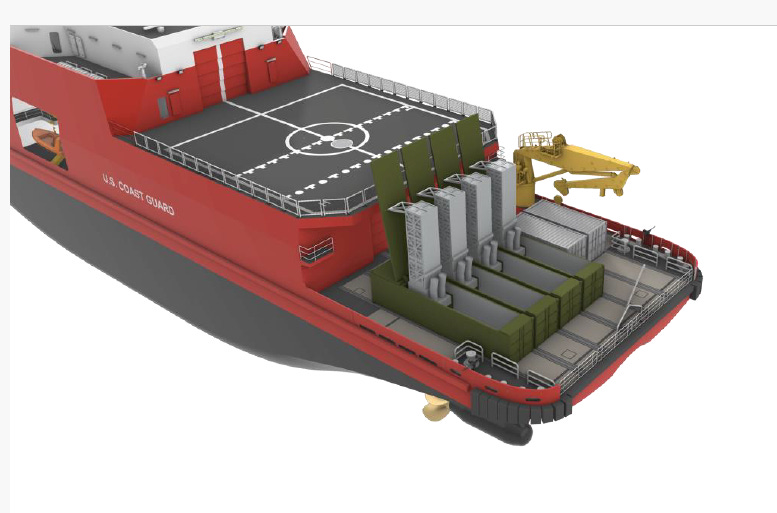

Crane and Deck Space:

The MPPS has both covered and deck space for storage, totaling up to 30 TEUs. (TEU= Twenty-foot equivalent unit, a unit of cargo equal to one twenty-foot container.) On deck, this is an ideal space for the Mk 70 launchers in the above graphic. Internally, there is space that could be used for other special mission cargo including UUVs, USVs, or UAVs. (This space is accessible via a vehicle ramp).

The design also features a crane for loading/unloading cargo. This crane could be used to change out Mk70 launchers, meaning the ship comes with an organic capability to ‘reload’ missiles.

Design History

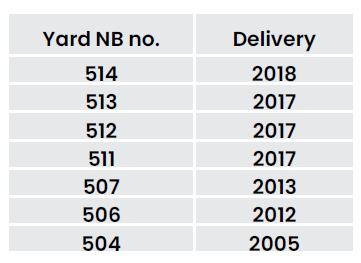

The MPPS (like the MPI) can trace its design lineage back to the FESCO Sakhalin, an icebreaker built for the Far East Shipping Company (FESCO) that was delivered by Helsinki Shipyard in 2005. Six additional vessels (in two different design iterations) have been built in Helsinki since then:

Let’s take a quick look at the design development across these vessels.

Generation 1: NB 504 FESCO Sakhalin

(Aker Arctic ARC 101, Helsinki Shipyard NB 504)

FESCO Sakhalin was a real breakthrough in icebreaker design.

The ship was designed a Platform Support Vessel and Standby Icebreaker for use in the Sea of Okhotsk. FESCO, the customer, had demanding requirements for icebreaking capability, open water capability, cargo carrying capability, and efficiency in a relatively shallow-draft vessel.

Aker Arctic detailed its design in a recent article titled The Father of Modern Icebreakers: FESCO Sakhalin:

With various technological achievements and breakthroughs in these past twenty years, one of the first major projects to capture these innovations in icebreaker design was FESCO Sakhalin (later SCF Sakhalin), Aker ARC 101. Considered to be the father of modern icebreaking among many at Aker Arctic, the project paved the way with proven icebreaker solutions that would come to define many modern icebreakers….

The vessel was to be classified as a DNV ICEBREAKER ICE-10 ice class icebreaker, equivalent to somewhere between a modern-day Polar Class 4 and Polar Class 3 icebreaker. Designed for Exxon and operated by the Far East Shipping Company (FESCO), the requirements for the ship were plentiful and stringent. With many intense performance requirements and no flexibility in changing the dimensions of the ship, all the stops had to be pulled.

….

Icebreaking innovation

The vessel was designed to break 1.5 m ice with 20 cm of snow ahead at a speed of 3 knots. Even more demanding were the requirements for operating astern in thick level ice and heavy ridges, along with the manoeuvrability needed for an offshore vessel and the strict draft requirements. These design drivers pushed towards an efficient icebreaking hull form with sloped sides and two azimuthing propulsion units with open propellers.….

Maximizing endurance and fuel capacity

In addition to icebreaking requirements, FESCO Sakhalin had a very stringent open-water endurance requirement. The vessel was to have 70 days of endurance, and fitting the necessary fuel to sustain such a long endurance required pushing the boundaries of icebreaker design.….

From the strict size limitations and extensive capability requirements, an icebreaker was born that would become the forefather of modern icebreakers. The double-wedged stern and twin azimuthing units, balanced icebreaking bow and other details in the vessel proved to be a strong reliable solution as an icebreaker.

The article isn’t that long and is definitely worth a read, especially for those interested in icebreaker design.

The design was very successful. As Aker notes:

Following very positive feedback from the first vessel delivered in 2005, six additional ships under the Sakhalin series were built in Helsinki from 2012 to 2018.

Generation 2: NB 506 and 507

(Generation 1 design licensed to Helsinki Shipyard as basis for Generation 2 design)

The second-generation design features the same hull with some internal improvements such as a new engine room arrangement and addition of a fourth diesel generator. Additionally, these ships can handle up to 195 persons in a ‘recovery area,’ in support of the ship’s role as an evacuation platform.

Notably, NB 506 was ordered in December of 2010 and delivered in December 2012- only twenty-four months later. NB 507 was delivered just a few months later in April 2013.

Generation 3: NB 511-514

(Design fully owned by Helsinki Shipyard)

According to Davie/Helsinki shipyard, the third generation featured an enhanced hull form, new engine configuration, and re-positioned propulsion units in a higher ice-class vessel. (DNV ICE-15 vs DNV ICE-10 previously, which equates to between PC3 and PC2). The hull forms, main dimensions, and propulsion systems are all the same. They share the following capabilities:

Fire-Fighting system for Offshore platform fire-fighting needs

DP2 (Dynamic Positioning 2)3 with multiple reference systems

Low flashpoint cargo tanks for supply of fuel to offshore platforms

As each vessel had a slightly different mission, each one was significantly customized.

NB 511 Gennadiy Nevelskoy:

Platform Supply Vessel

Classified as Special Purpose Ship

Moon Pool

Dry Cargo Handling System

6 x 6L32 Wärtsilä engines

NB 512 Stepan Makarov:

Icebreaking stand-by vessel, transports personnel

Classified as passenger ship

Moon pool ready

4 x 9L32 Wärtsilä engines

Ampelmann personnel transfer system

NB 513 Fedor Ushakov

Icebreaking stand-by vessel, transports personnel

Classified as passenger ship

Moon pool to support diving/ROVs for gas pipeline maintenance

4 x 9L32 Wärtsilä engines

NB 514 Yevgeny Primakov

Icebreaking stand-by vessel, transports personnel, can operate offshore anchors

Classified as passenger ship

Moon pool to support diving/ROVs for gas pipeline maintenance

4 x 9L32 Wärtsilä engines

Anchor-handling winch and stern roll.

Anchors with more holding power.

Additional diving support.

Ordered in May of 2015, 511 was delivered in March 2017 (34 months), 512 in July 2017 (38 months), 513 in October 2017 (41 months) and 514 in February 2018 (45 months).

If you’re keeping track, all four of these vessels were delivered within four years of the order.

Generation 4: The Multi-Purpose Polar Support Ship

That brings us to the current design iteration detailed at the beginning of the article. Although there were refinements to the hull and propulsion systems (particularly for the third generation), the hull form, dimensions, and propulsion have remained largely the same through the generations, with the major developments all being internal or topside.

Davie/Helsinki Shipyard is offering a quick build stating that a MPPS-100 is available from Helsinki Shipyard in 26 months from contract. They have the track record to back that up, too.

Thoughts and Comments

As a retired Naval Officer (and engineer) I can appreciate much about the MPPS design. While not designed to warship survivability criteria, it does have redundancy and survivability above ‘normal’ commercial icebreakers. It also includes current weapons systems and reserves power, space, and weight for future requirements. As China is working on a ‘heavy’ icebreaker and Russia is aiming to replace much of its aging fleet, having a more capable vessel than the Coast Guard’s RFI requirements, with room for growth, seems a prudent course.

The design’s ‘standard’ moon pool intrigues me, as one criticism of armed icebreakers is that they cannot conduct Anti-Submarine Warfare (ASW) because icebreaking is so loud as to make SONAR systems useless. Absent the capability to detect and counter submarines, icebreakers will not survive long in combat. Deploying ASW UUVs (or even ROVs) via a moon pool may challenge that criticism in the future.

As designed, the MPPS weapons systems stack up well to those of the Russian Project 23550 “Combat Icebreakers4.” The first (of a planned four) of these Russian vessels has a 76.2mm gun and space for up to 8 Kalibr missiles in a containerized system. Note that the ship has no air defense capability. Additionally, I can find no reports of the first ship operating with the ‘Club-K’ containerized launchers installed.

The MPPS also out-guns Canada’s Harry DeWolf-class Arctic Offshore Patrol Vessels, which feature 1 x Mk 38 Mod 3A 25mm gun system and 2 x M2 .50cal crew-served mounts.

When it comes to the ship design, some may note that the MPPS is based on twenty-year old hull design. The other side of this, though, is that demand for the vessels continued, amassing a track record of performance. According to Davie this track record amounts to:

7 ships, [with a] total 85 years of winter operation in Arctic regions. One vessel passed [through the] North-East Sea route without escort in 8.5 days

Noting the Russian names and current service supporting Russian oil exploration, some may doubt whether these vessels meet modern western standards. Davie notes that:

Even though the vessels have Russian names, they were all built to comply with Western standards and class rules. There were global/U.S. companies (such as Exxon) behind these offshore programs.

The vessels were all classed by DNV (Det Norske Veritas), a Norwegian classification society. The projects they support- Sakhalin I and Sakhalin II- were joint ventures with international companies that included Exxon (Sakhalin I) and Royal Dutch Shell (Sakhalin II) that unwound following Russia’s escalation and continuation of its war against Ukraine in 2022.

Bottom line: With its proven track record, redundancy and survivability, current weapons systems, and room for growth this vessel seems to be a good fit for the Arctic Security Cutter mission set. (Although we have yet to see what the U.S. Coast Guard is actually saying about its mission requirements).

I’d like to do a deep dive into any other designs out there being marketed as a possible U.S. Coast Guard Arctic Security Cutter. So far, I only know of two such designs (the MPI and MPPS). If anyone knows of any others, please let me know. Thanks!

It’s been a busy week. There is much more still to write about, including China’s recent activity in the Arctic, and Davie/Helsinki shipyard beginning production work on their Canadian Polar Icebreaker only six months after contract award. Subscribe so you don’t miss any of the latest news or analysis concerning icebreakers. And maybe sometime soon I’ll even have a few minutes to write about something else.

Until next time-

All the Best,

PGR

Davie Defense is, among other things, managing the purchase of Gulf Copper’s Texas Shipyards, described here:

Dynamic Positioning refers to a vessel’s ability to maintain a precise position automatically. DP2 classification means that the DP system will continue to maintain station with the failure of an active component.

Contrary to all of the recent articles, the Project 23550 vessels are PC3 equivalent patrol vessels. They do not meet the additional requirements for icebreakers, and as such are not icebreakers.

Peter, I'm a recent Canadian subscriber and really enjoy your knowledgeable writing on all things Icebreaker related. These are exciting times in Arctic affairs and in particular, the fact that Canada has now begun the building stage of the Seaspan and Davie/Helsinki PC2 vessels, has completed the RCN AOPS class and is deep into the construction of the CCGS Donjek and Sirmilik AOPS. I look forward to reading many more of your articles. You've become my primary go-to source for the latest accurate information. Cheers! Ken G.

Thanks Peter, loved the detail in the article. Be great to see some more about Antarctic capabilities too.