Finland's Icebreakers

A look at Finland's current fleet shows the evolution of icebreaking technology.

Note: This is part of a continuing series on Arctic policy and icebreakers. To look at previous articles, click here.

Finland is the only nation in the world where all of the major ports ice up every winter. In the satellite image below, from March of 2010, you can see white ice surrounding the entirety of Finland’s coastline. Norway doesn’t have this problem, as the Gulf Stream keeps its coast virtually ice free. Some of Sweden’s and Russia’s ports remain open even in the harshest winters. For Finland, ice could shut down traffic in and out of its ports from November through April- roughly six months out of the year.

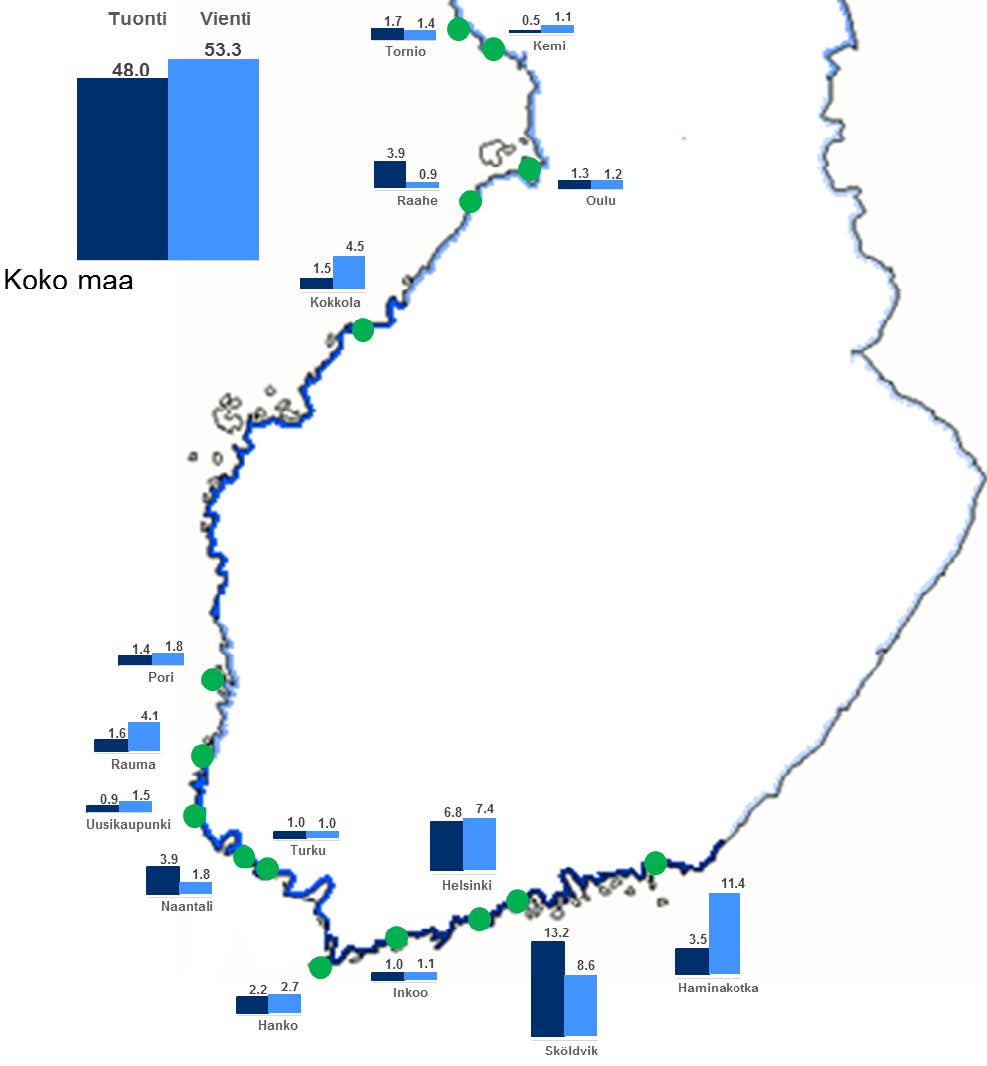

This matters, because for Finland 94% of exports and 97% of imports are carried by sea. And the major ports cover the entire coastline, as shown in this graphic that depicts the throughput of Finland’s fifteen largest ports.

Today, Arctia, the state-owned operator of Finland’s icebreaking fleet, keeps 23 of Finland’s seaports open all year round.

Arctia only needs to send its entire fleet to sea once or twice in decade, but all icebreakers need to be available each season as ice conditions are notoriously difficult to predict. Ice conditions are dependent heavily on wind and temperature fluctuation, not just the temperature. In Finland, fast ice- ice connected to the shore- forms along the coast. Wind affects ice in a similar manner to the waters of the open sea, creating movement and pressure, causing it to drift and compress. When drifting ice meets the pack ice, it creates ridges and ice walls. Like an iceberg, about 10% of the wall is above the water; the rest is below. The deepest wall ever measured in the Baltic Sea went 31.5m deep1. Winds also move the cut fairway channels, which is dangerous in Finland’s narrow, shallow, and rocky channels, meaning that icebreakers have to continually cut new channels.

This year, all of Arctia’s icebreakers were at sea by February 25th. As of March 22nd, Fennica and Voima have returned to port, but ice conditions remain tough in some port areas:

In the Bay of Bothnia the ice conditions are still very difficult. The ice is ridged, rafted and hummocked. The S-SW winds push the ice cover towards the northern shore of Bay of Bothnia. For the time being, the deep fairway to Kemi and Tornio cannot be accessed, and the ships need to navigate via the narrow fairway closer to shore. In Sweden, the deep fairway leading to Luleå cannot be accessed, and the fairway to the port of Kalix/Karlsborg in Sweden is completely closed: no ships have entered the port in more than two weeks2.

Arctia’s Fleet:

Arctia operates eight icebreakers (and one harbor icebreaker, the Ahto) of varying types and ages:

Finland’s Conventional or Traditional Icebreakers

Five of these (Voima, Urho, Sisu, Otso, and Kontio) are considered conventional or traditional icebreakers, designed primarily for Baltic Sea usage. (For a video of what icebreaking in the Baltic looks like, see here or here.)

Baltic breakers differ from their Arctic cousins. The decisive factor is not extreme engine power but agility. The thickness of the ice rarely exceeds 80 centimetres, but during severe winters there may be dozens of ships awaiting assistance in front of the busy ports. The icebreaker then has to cut the ships loose, organize them into a convoy, and assist them into port quickly3.

Traditional Baltic breakers can operate in all the ice conditions of the Baltic but are poor open-water ships in the waves. They are over-stable. Their centre of gravity is low down and the moment that straightens the traditional breaker is violent. The hull shape of a Baltic breaker is like an egg4.

Voima (1954) was the first icebreaker to be fitted with four screws, two in the bow and two in the stern. Four sister vessels were built; three were sold to the Soviet Union and the fourth to Sweden. Voima, which was substantially upgraded in the late 1970s, is the last of these to remain in operation.

Urho (1975) and Sisu (1976) followed, also with four screws. Their hull designs were refined based on ice trials data and, for the first time, using data obtained from scale model trials in specially designed ice test tanks. Three sister ships, the Atle, Ymer, and Frej, are current operated by the Swedish Maritime Administration.

Otso (1986) and Kontio (1987) were designed to be more cost-effective than their predecessors, with an air bubbling system replacing the two forward screws, a cheaper hull design, and smaller crew permitted by advances in automation. They are typically the first icebreakers to go to sea in the Bay of Bothnia, with the Urho and Sisu taking over when the ice conditions worsen.

Technological transition

In the 1990s, Finnish engineers, in conjunction with what was then Wartsila Shipyard (now Helsinki City Shipyard, owned by Davie of Canada) and the Finnish Maritime Administration, developed the world’s first electrical azimuth thruster assemblies, designed to replace the traditional shaft, screw, and rudder. Although similar mechanical assemblies had been used for tugboats, these assemblies were much more powerful. Vessels equipped with them would be more maneuverable and would not require rudders or lengthy shafts.

During an upgrade of the buoy tender Seili in 1991, a single electric steerable pod replaced her propeller and rudder. The results were stunning; not only did Seili perform better in breaking ice going forward, but it made even better headway in reverse, even though its stern had not been designed for ice breaking. The company behind this innovation was later bought by ABB, and its propulsion pods are now known as Azipods.

The stern first icebreaking development led to a revolution for ice capable vessels known as the Dual Acting Ship concept, in which a vessel is designed with a hull suitable for open water going forward and navigation through ice while going astern. Azimuth propulsion is not just suited for icebreakers; indeed, most of the world’s cruise ships now use some form of it due to the maneuverability and efficiency obtained by using aximuth propulsion. ABB (which manufactures Azipods in Finland) and Steerprop (a Finnish company) are leaders in the development and manufacture of electric and electical-mechanical driven propulsor pods5.

Multi-purpose Icebreakers

Around this time, Finland was looking to build new icebreakers to replace the aging Tarmo class. ABB, partnered with Masa-yards, planned to build them with electric azimuth units. The contract however went to Rauma Yards instead, using electrical-mechanical Z drive units. Three vessels were built, MSV Fennica (1993), Nordica (1994) and Botnica (1998).

Arctia’s multipurpose vessels MSV Fennica and Nordica are unique vessels in the world. They are powerful icebreakers with characteristics ideal for tasks that require manoeuvrability and precision. Multipurpose icebreakers are capable of performing highly demanding tasks in environments such as oil and gas fields everywhere in the world.

The ships have excellent icebreaking characteristics and are well-suited to DP (dynamic positioning) operations, towing merchant vessels in difficult ice conditions, and providing ice management services to the oil industry in Arctic areas. With the aid of winches, cranes and A-frames, the vessels can switch rapidly from one task to another. Thanks to Arctia’s sizable investments, the ships meet all of the strict criteria and guidelines applying to offshore operations6.

Fennica and Nordica were designed and built for use in ice and open ocean conditions. Changes in hull shape, the introduction of two 360-degree steerable Aquamaster Azimuth thrusters in place of rudders (as discussed above), and an active stability system overcame some of the challenges of taking earlier Baltic icebreakers to the open ocean. Their smaller sister ship, the Botnica, was sold to Estonia in 2012.

The reason Finland built these Multi-purpose vessels was to take advantage of the off season. Icebreakers are needed in Finnish waters from November through May, but the rest of the time they sit unused, requirng maintenance and upkeep but earning no revenue. Multi-purpose icebreakers could be earning money from charters during this downtime. Nordica and Fennica have supported oil operations in the North Sea and the Chukchi Sea (off of Alaska). Nordica also supported oil and gas production in the Sea of Okhotsk and owns the record for the earliest transit of the Northwest Passage, completed during her 2017 return from Sakhalin. They’ve also worked in unlikely places for icebreakers, such as off the coast of Brazil and Angola.

These days, there isn’t much demand for icebreakers to support commercial work (outside of Russia, which uses its own vessels), although Arctia did sign an agreement with Baffinland Iron Mines Corporation of Canada to provide one multipurpose icebreaker during the 2023 to 2025 shipping seasons. This is the first “off-season” work for these ships since 2017.

Polaris (2016)

IB Polaris, the first LNG powered icebreaker in the world, joined Arctia’s fleet in September 2016. This unique vessel is able to use both liquefied natural gas (LNG) and low sulphur diesel oil as fuel. The use of LNG significantly reduces carbon emissions, making IB Polaris also the most environmentally friendly diesel electric icebreaker in the world.

Icebreaker Polaris is a true masterpiece of Finnish shipbuilding expertise. Innovative design is used for example in the vessel’s hull form and propulsion unit arrangement. The vessel is equipped with three Azipod propulsion units rotating 360 degrees which enables excellent maneuvering qualities. The icebreaking capacity of IB Polaris is 1,2 meters at a speed of 6 knots7.

Polaris shows the advantages that this new technology brings, especially when compared to older technology vessels such as the U.S. Coast Guard’s Polar Star, delivering comparable icebreaking ability at less than half of the horsepower:

…and Polaris took about three years to build at a cost of about 150 Million U.S. Dollars. Considering inflation, it would probably cost around 200-225M USD today. Compare this time and cost with the U.S. Coast Guard’s current Polar Security Cutter Program, and you can see why many people believe the USA should seek foreign assistance in building new icebreakers.

To see the maneuverability and capability of Polaris during her ice trials, check out this video:

Concluding Thoughts:

During my time in Finland, I’ve heard repeatedly- from American officials, mainly- that Finland only builds and operates “Baltic Sea icebreakers.” I imagine that the folks who say such things are imagining small lakes and ponds with level ice, not the challenging ice ridges and hummocks that are a feature of the Gulf of Bothnia. It is these challenging ice conditions, and the Finnish response to them, that have provided the main impetus for the development of modern icebreaking technology. Finnish firms have developed and refined this technology by designing and building vessels to meet a variety of conditions, including multi-year Polar ice operations, to satisfy the specific needs of their customers.

This customization is why it is difficult to compare icebreakers across nations, and across time. Horsepower is no longer an effective measure. The tradeoffs between maneuverability and open sea stability can be managed on a case-by-case basis. Even Polar Class (which we will get back to) often depends on the ship’s purpose rather than its icebreaking capability.

According to Business Finland, “Finnish companies have designed about 80 percent of the world’s icebreakers, and about 60 percent of them have been built by Finnish shipyards.” Yet the Congressional Research Service’s Report and other official reports downplay this option year after year, apparently without seeking updated information.

We will take a deeper look at the ability of Finland’s firms to design and build icebreakers in a future installment.

Until then, thanks for reading, subscribing, and spreading the word.

Like by pressing the heart if you want to see more posts like this and consider sharing with a friend.

All the Best,

PGR

Ari Turunen and Petja Partanen, Brute Force: The Story of Finnish Icebreaking, 2014. p 36. This book is an excellent resource on icebreakers, ice-capable ships, and the development of the associated technologies.

Elisa Mikkolainen, Director, Waterways Department at Finnish Transport Infrastructure Agency, via LinkedIn

Brute Force, p 127

Brute Force, p 154

Information on the development of Azipods comes from Brute Force, p 84-90

One has to be totally blind or simply bought off by special interests to fail to understand that

the Fins abilities with ships and ice are simply unmatched, and have been that way for as long as one can remember explorers withing to go into the ice.