The 'Silicon Valley' of Icebreaking

A quick tour through Finland's shipbuilding ecosystem following in the virtual footsteps of a visiting U.S. delegation.

A couple of weeks ago, RADM Tom Anderson, U.S. Navy, led a delegation to Finland consisting of leaders in U.S. Coast Guard acquisition and U.S. Navy ship design. RADM Anderson is the Program Executive Officer (PEO) for ships— that means he oversees all of the U.S. Navy’s shipbuilding programs. The delegation visited many sites related to icebreaker design and construction.

Let’s take a look at Finland’s shipbuilding industry by following his itinerary, as published through PEO Ships LinkedIn page1:

Day 1

The first day included visits to the U.S. Embassy, Finnish Ministry of Defence, and Helsinki Shipyard.

We’ll skip the Embassy and MOD visits and start with Helsinki Shipyard:

Helsinki Shipyard is the world leader in the design and construction of icebreaking and high ice-class vessels for demanding and harsh environments. Over 50% of the global icebreaker fleet has been built at our facility and we pride ourselves on our pioneering position in icebreaking technologies which range from hull design and materials to propulsion systems.

Between 2010 and 2020 Helsinki Shipyard built nine icebreakers of PC4 or higher ice class (including Polaris and Baltika). Not limited to building small vessels, in 2019 it delivered a PC3 equivalent 50,000 DWT icebreaking tanker capable of operating independently along Russia’s Northern Sea Route. Most recently, the Helsinki Shipyard has built three PC5 Arctic Expedition Cruise Ships for Swan Hellenic.

Although ownership has changed hands over the years, Helsinki shipyard dates back to 1865. Most recently, in November 2023, Canadian shipbuilder Davie purchased Helsinki Shipyard. Davie is a strategic partner in Canada’s National Shipbuilding Strategy and holds contracts to build six program icebreakers and one polar icebreaker for the Canadian Coast Guard.

Day 2

The second day itinerary included visits to the shipyards Rauma Marine Constructions and Meyer Turku.

Meyer Turku: Finland’s largest shipyard, known primarily for building environmentally friendly cruise ships. Recently delivered Icon of the Seas, the world’s largest cruise ship, to Royal Caribbean. As Meyer does not build icebreakers, I don’t have too much to say about it.

Rauma Marine Constructions (RMC): Specializes in building car and passenger ferries, icebreakers, and government research vessels. Currently, RMC is building four multi-mission, ice-capable Corvettes for the Finnish Navy. Recently, RMC completed the ferry Aurora Botnia (2021) which is designed to run across the Gulf of Bothnia without icebreaker assistance, the ice-capable Offshore Patrol Vessel Turva (2014) for the Finnish border guard, and the PC 5 supply and research vessel S.A. Agulhas II for South Africa (2014). Three of Finland’s icebreakers, the Fennica, Nordica, and Botnica, were built in the Rauma shipyard2 between 1993 and 1998.

Day 3

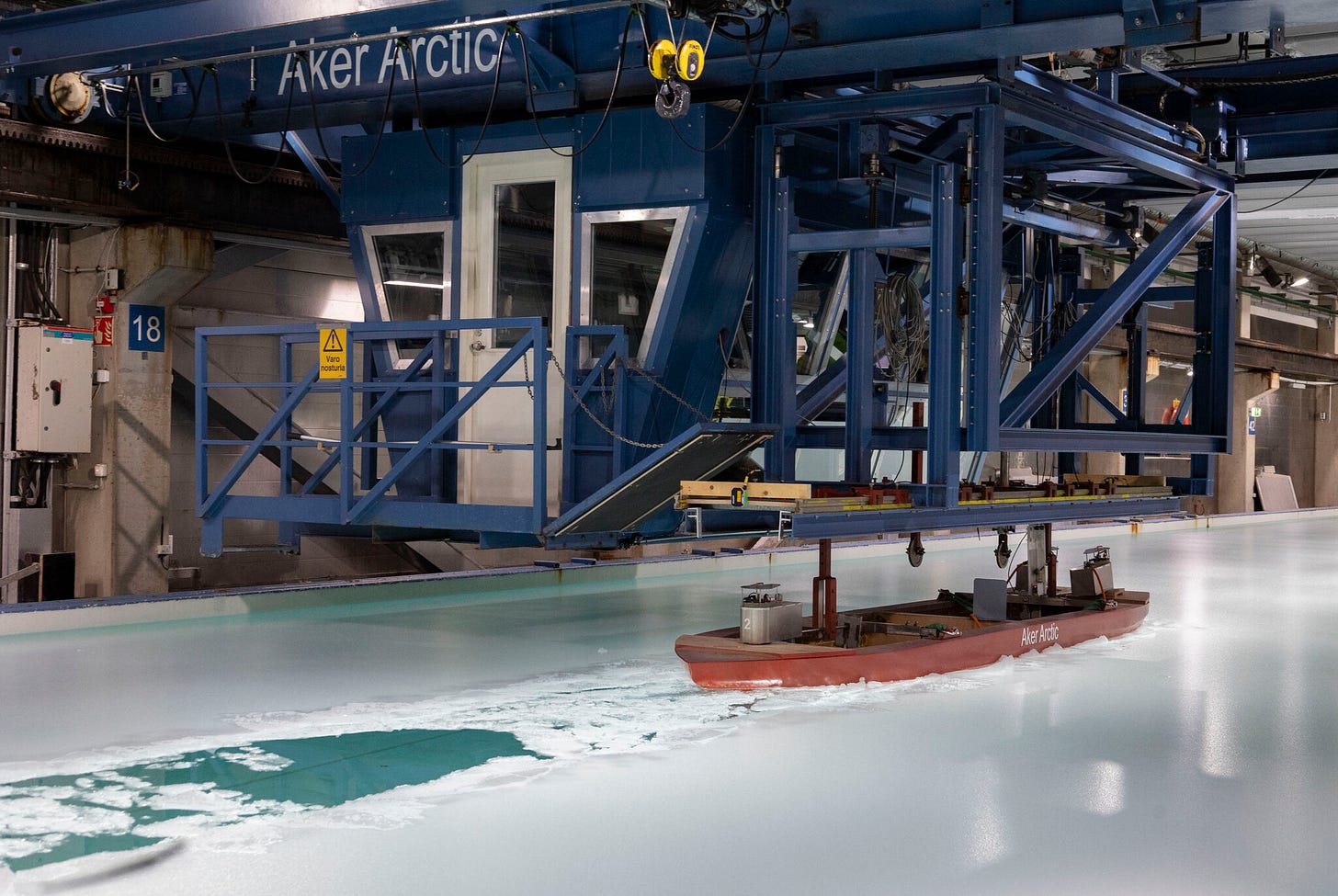

Day three brought our delegation to Aker Arctic Technology. Aker specializes in the design of icebreakers and ice-capable ships and has designed the majority of these types of ships in the world. As part of its facility, Aker operates a third-generaton ice tank for model testing. With this history it is no surprise that Aker has worked with the U.S. Coast Guard before:

Aker Arctic and its predecessors have also been involved in Coast Guard icebreaker projects, providing extensive conceptual development and design support, which included hull form development and propulsion line engineering for the medium icebreaker USCGC Healy. Aker Arctic also developed the vessel concept for the Great Lakes icebreaker USCGC Mackinaw in cooperation with the USCG. The concept was based on the Double Acting Ship (DAS(TM)) principle and podded propulsion system. In both projects, the company was also responsible for model testing. Aker Arctic has also done concept design in co-operation with VARD Marine (Canada) for the Canadian Coast Guard (CCGS) Polar Icebreaker John G. Diefenbaker. It will be the most powerful diesel-electric icebreaker in the world with advanced hull form and a hybrid azimuth/ shaftline propulsion system.

The delegation also visited ABB’s Azipod assembly plant:

ABB, along with the Finnish company Steerprop and Kongsberg Maritime, supply 360-degree steerable propulsion units of the type commonly seen on cruise ships and modern icebreakers.

A visit to Finland wouldn’t be complete without a stop by Katajanokka to visit Arctia, the operator of Finland’s icebreaking fleet. It was always a highlight of these delegations to tour some of the ships and speak with their Captains and crew.

For more information on Finland’s icebreaking fleet:

Finland's Icebreakers

Note: This is part of a continuing series on Arctic policy and icebreakers. To look at previous articles, click here. Finland is the only nation in the world where all of the major ports ice up every winter. In the satellite image below, from March of 2010, you can see white ice surrounding the entirety of…

Business Finland publishes a pamphlet that provides detail on the above companies, as well as many of the smaller firms that form a part of Finland’s global expertise on icebreakers.

Closing thoughts

Despite countless visits of this sort over the past decade, very little of the information presented has made its way into the U.S. Coast Guard’s discussions about how to procure polar icebreakers. At the Polar Security Program continues to fall behind, it becomes increasingly important for decisionmakers in the United States to understand these capabilities.

The May 2024 Congressional Research Service report still reads as it did in 2017:

Another potential issue for Congress concerns the possibility of building polar icebreakers for the U.S. Coast Guard in a foreign shipyard. Shipyards in Finland, for example, reportedly have expressed interest in building polar icebreakers for the U.S. Coast Guard. Some observers believe the acquisition cost of Coast Guard PSCs could be reduced, perhaps substantially, by building them in a foreign shipyard, such as a shipyard in Finland or in one of the other Nordic countries that is experienced in building icebreakers. Other observers question whether icebreaker designs offered by foreign shipbuilders would meet (or be a cost-effective way of providing) the Coast Guard’s desired capabilities for PSCs, which include capabilities for performing Coast Guard missions other than icebreaking. An October 9, 2017, press report states:

Finland, the world leader in icebreaker design and construction, could help pull the United States out of its icebreaker crisis, a diplomat said at a business conference in Anchorage last week. “The U.S. is now in dire straits about its own icebreaker fleet. They only have two and they are both seriously outdated. We can help,” Stefan Lindstrom, Finland’s Los Angeles-based consul general, said in a presentation at last week’s Arctic Ambitions conference held by the World Trade Center of Alaska.... If the U.S. makes a decision to buy a replacement from overseas, Finnish shipbuilders could respond quickly, Lindstrom said. In Finland, a shipyard can build and deliver a polar-class icebreaker within 24 months after a contract is signed—a sharp contrast, Lindstrom said, to the extended discussions that the U.S. Coast Guard and Congress have had over planning for potential new icebreakers. And the costs for a Finnish-designed and Finnish-built polar-class icebreaker is about 200 million to 220 million Euros ($235 [million] to [$]258 million), he said. That’s far lower than the price tag being discussed in the US. “I have serious difficulties, however, understanding how you can pay a billion for an icebreaker that costs one-fifth of it if you order it from abroad,” Lindstrom said. “But I'm not going to go into those political situations.”

It is unclear from the above-quoted remarks whether the €220-million polar-class icebreaker being referred to would qualify as a heavy, medium, or light polar icebreaker, or to what degree it would meet the Coast Guard’s desired capabilities for PSCs, which include capabilities for performing Coast Guard missions other than icebreaking.

As that quote is from 2017, the price point (200-220 million Euros) is quite outdated because of inflation. However, I know- with certainty- that the U.S. Coast Guard, U.S. Congress, and other groups within the U.S. Government have received updated information on the cost, design/construction timeline, and the capabilities of foreign designed and built icebreakers that meet or exceed the U.S. Coast Guard’s mission requirements.

It’s time for some of the information learned by these delegations to enter the public discussion.

Thanks for reading. If you like what you’ve seen, press the heart and subscribe to make sure that you never miss an update. Consider sharing with a friend or fifteen; it takes me some time to research and write these articles, so I’m happy to see them spread far and wide. It’s important to keep this conversation going.

Until next time.

All the Best,

PGR

All photos come from PEO Ships LinkedIn posts.

The Rauma Shipyard was known as Aker Finnyards at the time. Because of ownership changes and changes in corporate structure RMC does not own the legal right to the designs or the design credit for them (Nordica, Fennica, Botnica).

I prefer to Buy American; but sometimes you have to buy an import. Icebreakers are one of those times.