Does the Icebreaker Le Commandant Charcot Meet U.S. Coast Guard Standards?

Comparing Commercial Specifications and MIL-SPEC suggests that yes, she does, making a strong case for future commercial builds.

If you are new to Sixty Degrees North, you might not be familiar with Le Commandant Charcot. This remarkable vessel is the world’s first (and only) Polar Class 2 icebreaker and has been called “NATO’s most capable icebreaker.” She is also a French cruise ship.

I often cite Charcot as an example of successful commercial icebreaker program. In past articles I’ve compared her directly to the U.S. Coast Guard’s Heavy Icebreaker Polar Star and the requirements for the planned Polar Security Cutters (PSC).

This comparison results in some pushback. Yes, Charcot is a capable ship. Yes, she was built in less than six years for about $340 million. But as some have pointed out, she’s a commercial ship, not designed and built to defense standards (MIL-STD) and has components that don’t meet the defense specification (MIL-SPEC).

Before continuing, let’s note that the PSC itself will feature mixed standards:

USCG estimates that some percentage of the new polar icebreaker will have MIL-SPEC requirements for design, materials, construction, and testing but has not indicated what the mix of military and commercial might be. (p. 70)

This quote is from a 2017 report to Congress by the National Academy of Sciences titled “Acquisition and Operation of Polar Icebreakers: Fulfilling the Nations’s Needs.”

A quick side note: This is one of the most comprehensive reports on the USCG’s icebreaker procurement that I’ve ever read. I initially did not take it as seriously as some others because of its source. But in looking at the mandate of the Transportation Research Board, the composition of the committee that wrote the report, and all of the people they interviewed, it became clear why the report is so good. The information in the Appendices- especially B, C, and D- is very detailed. Additionally, there was Congressional Testimony accompanying its release by RADM Richard D. West, U.S. Navy, (retired), the committee chair. Watching the testimony in preparation for this article left me somewhat frustrated, as the USCG would have been better served if it more closely followed the committee’s recommendations.

Back on topic.

Is an icebreaker built to commercial standards (such as Le Commandant Charcot) actually built to a lower standard than a partial MIL-SPEC vessel (such as the Polar Security Cutter)? Let’s dive in.

Defining Commercial Standards and Defense Specification (MIL-SPEC)

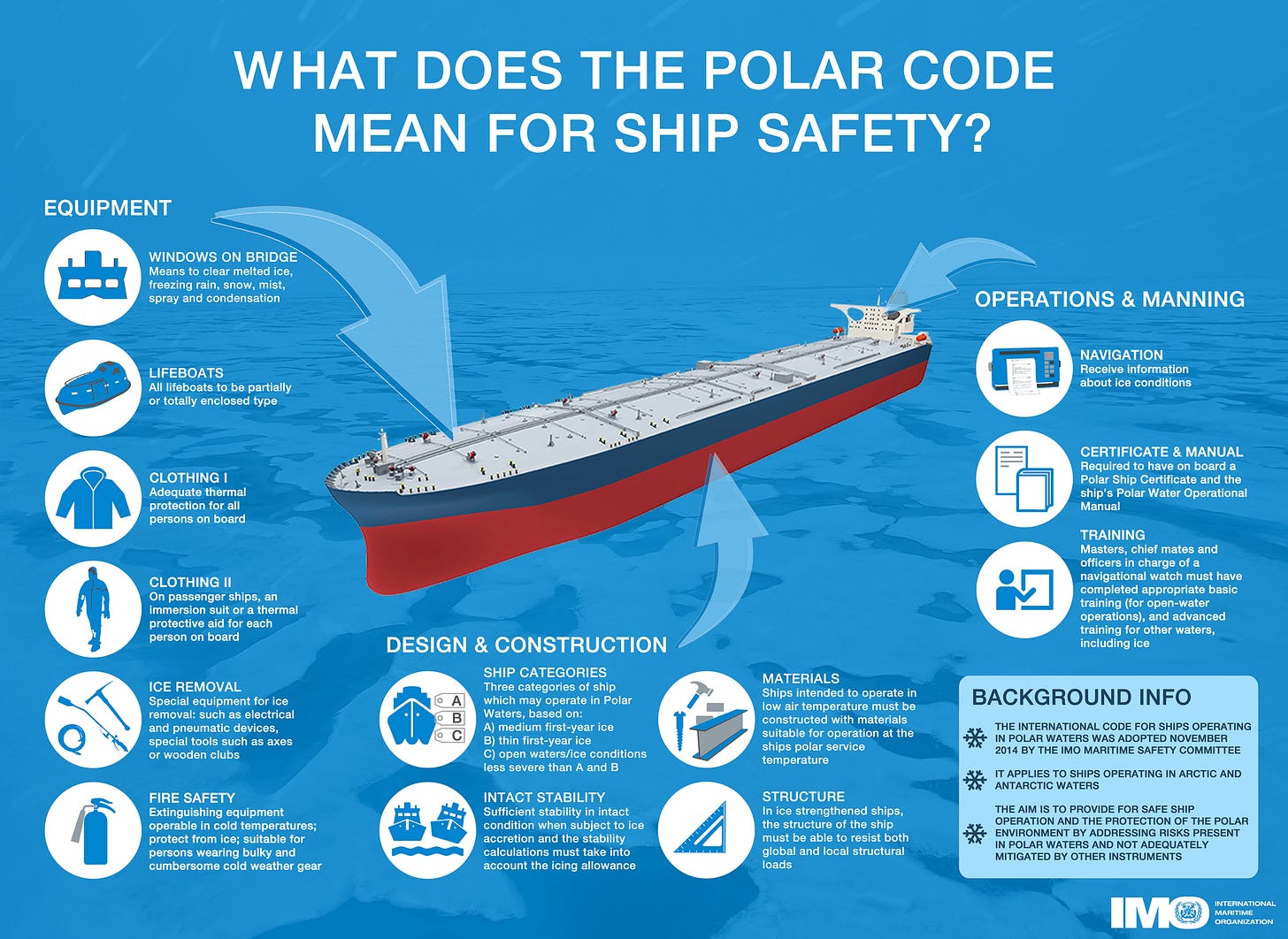

International/Commercial standards, in the context of icebreaking or ice class vessels, refer primarily to the International Maritime Organization (IMO)’s Polar Code and the International Association of Classification Societies (IACS)’s Polar Class1. They apply to vessels that will operate in the polar regions (which are defined in the Polar Code) in addition to the requirements of the International Convention for the Safety of Life at Sea (SOLAS) and the International Convention for the Prevention of Pollution from Ships (MARPOL).

Polar Code

The Polar Code is relatively new, having entered into force on January 1, 2017. Here are some details:

The chapters in the Code set out goals and functional requirements specifically covering: ship structure; stability and subdivision; watertight and weathertight integrity; machinery installations; fire safety/protection; life-saving appliances and arrangements; safety of navigation; communications; voyage planning; manning and training; prevention of pollution by oil; control of pollution by noxious liquid substances in bulk; prevention of pollution by harmful substances carried by sea in packaged form; prevention of pollution by sewage from ships; and prevention of pollution by garbage from ships.

The Code will require ships intending to operate in the defined Arctic waters and the Antarctic area to apply for a Polar Ship Certificate, which would classify the vessel as either:

• Category A - ships designed for operation in polar waters in at least medium first-year ice, which may include old ice inclusions

• Category B - a ship not included in category A, designed for operation in polar waters in at least thin first-year ice, which may include old ice inclusions

• Category C - a ship designed to operate in open water or in ice conditions less severe than those included in categories A and B.

The design and construction requirements of the Polar Code point directly to the IACS Polar Class requirements.

Polar Class

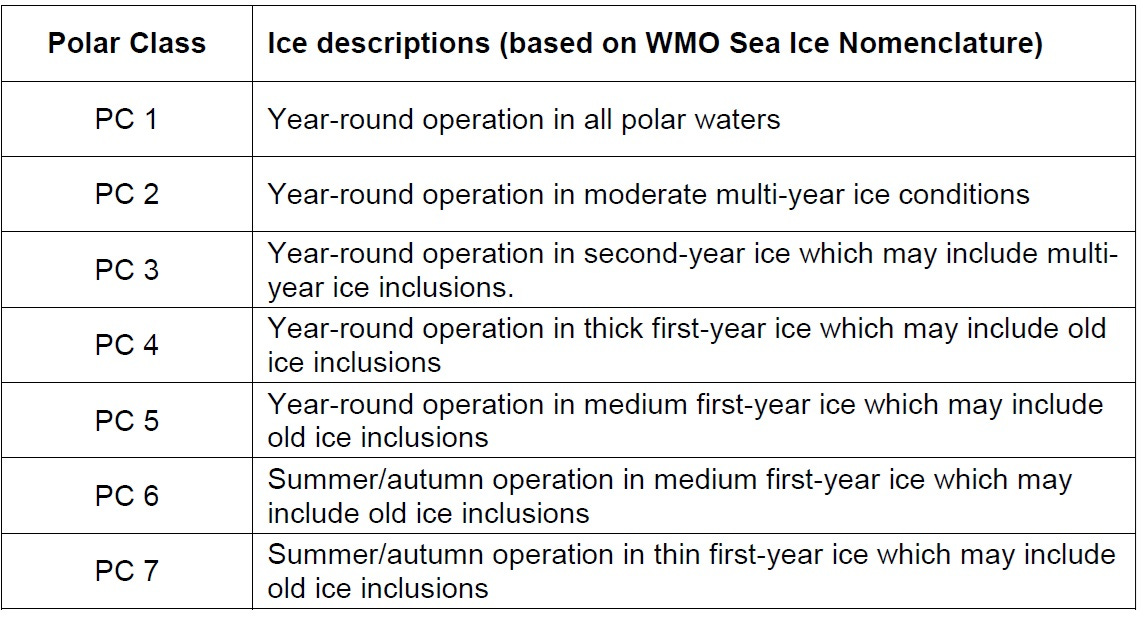

The IACS Unified Requirements (UR) for Polar Class Ships went into effect for ships contracted after July 1, 2007; Revision 4 is currently in effect for vessels contracted after January 1, 2021.

You can find the Unified Requirements for Polar Class Ships here. Note that the IACS does not evaluate and classify vessels itself. Rather, its standards are incorporated into the rules of classification societies such as the American Bureau of Shipping, Bureau Veritas, Lloyd’s Register, and others. These classification societies may have their own requirements and levels (think Finnish-Swedish Ice Class, Canadian Arctic Class, Russian ice class, etc). However, classification societies give Polar Class notation to vessels that meet the requisite IACS unified requirements. For example, you can see the Bureau Veritas (BV) rules here and the American Bureau of Shipbuilding (ABS) rules here.

If you dig into these rules, you will find that their rules for Polar Class Ships are essentially the same as the UR- but that BV and ABS have different additional requirements to earn the ‘icebreaker’ classification.

Here are the general capabilities associated with vessels built to the respective Polar Class requirements (ice descriptions are based on World Meteorological Organization Sea Ice Nomenclature):

That’s a very basic overview of where the commercial standards for icebreakers come from. Let’s take a quick look at Le Commandant Charcot’s Class notations (from BV):

She is classified as an Icebreaker 3 (bow), Icebreaker (4) stern. These are in accordance with BV’s specialized requirements for icebreakers that I mentioned above. You can see the Polar Code classification of POLAR CAT-A in the Service Notation line, and the IACS classification of POLAR CLASS 2 in the ‘Additional Class Notations’ section. For a detailed explanation of the other terms, see here:

Defense Specification/MIL-SPEC

The National Academy of Sciences (NAS) report that I referenced above uses MIL-SPEC in an over-arching way, meaning not just defense specification but rather

all military standards that guide design, procurement, installation, testing, and maintenance of the ship or ship systems. These include Federal Standard, design data sheets, NAVSEA technical manuals, and other legacy documents that USCG may choose to invoke for its polar icebreakers. (p. 71)

As mentioned above, the USCG does not build its vessels to full MIL-SPEC. According to the NAS report, the USCG was most likely to use MIL SPEC for

diesel engines, noise and vibration systems, propeller balancing systems, propulsion shafting systems, and air and exhaust systems. (p. 71)

The NAS report also considers stability and survivability standards.

Originally, I had hoped to find and compare specific standards in a head-to-head fashion. But, the sheer volume of defense specifications and the difficulty in finding the correct ones has made that task far too difficult. I will do some head-to-head comparison of the PSC to commercial standards later. But for now, I can offer some examples of the defense requirements that I found applicable to U.S. Navy vessels.

T9070-AF-DPC-010-07901 Design Practices and Criteria for U.S. Navy Surface Ship Stability and Reserve Buoyancy: requires different stability calculations and assumes a higher level of design damage (12.5% of waterline damage vs 4.5% for Polar Code, for example).

OPNAVINST 9070.1B Survivability Policy and Standards for Surface Ships and Craft of the U.S. Navy: describes in general what makes a ship survivable. Looks at susceptibility of ships to damage, the reduction of vulnerability to damage, and the recovery following damage. Susceptibility is reduced through active and passive defense (weapons system), vulnerability is reduced by hull strength and specific countermeasures for chem/bio/nuclear attack, recovery is enhanced through redundancy and the installation of damage control systems.

With access to USCG and USN experts, the NAS Committee undoubtedly had better knowledge of what standards are typically employed for USCG vessels- sufficient knowledge to provide an estimate of the additional costs incurred should full or mixed MIL-SPEC be required.

With that in mind, let’s look at four specific areas where the NAS report addressed Civilian Spec vs MIL-SPEC.

Damage Stability and Survivability

From the NAS report (Appendix D, page 73)- Emphasis mine:

Application of damage stability requirements according to international standards would be more appropriate for an icebreaker and may lead to greater safety in ice conditions, while simplifying the design of the ship and reducing its cost. The IMO Polar Code, which applies to icebreakers, has extensive damage requirements oriented to the type of damage expected from ice, with longitudinal extent of shell damage and opening to the sea along the waterline, of up to 4.5 percent of the length of the ship (about 20 feet). The code also requires a high standard for stability after flooding from damage to the side shell (s1 equal to 1 or greater)2 when the Safety of Life at Sea (SOLAS) damage stability requirement is applied….Overall, the committee anticipates that applying international and polar damage stability requirements will result in a ship that is safer in ice conditions without having to manage the more costly and difficult-to-design changes needed to meet MIL-SPEC requirements for a ship anticipating combat. In assessing the subdivision and the appropriate damage stability criteria, the committee recognizes the high level of crashworthiness inherent in icebreakers due to the robust hull structure and plating required for operations in heavy ice.

In other words, for everyday execution of USCG missions, a polar icebreaker built to commercial class standards would be safer in ice than a MIL-SPEC vessel, although the latter may be more survivable in combat. For the moment, considering the Navy’s instruction on survivability above, the best thing to do if you want to help an icebreaker survive combat is to escort it with a capable combatant.

Much has been made recently about the new Russian Project 23550 icebreaking patrol ships. These PC3 equivalent ships have a deck gun, some machine guns, and a close-in-weapons system. Note that Canada and Norway also operate ice-capable patrol vessels armed with guns (Canada’s Harry DeWolf-class and Norway’s NoCGV Svalbard). The Russian vessels are more capable in the ice, and in the future, they may carry the ‘Club K’ Kalibr cruise missile system contained in a shipping container. The ‘Club K’ threat is not limited to these ships, as the containers can be fastened to any vessel with space for them.

It is not clear how effective these Russian ‘Combat Icebreakers3’ would be while slowly maneuvering in ice, especially with their limited self-defense capabilities (i.e. no surface-to-air missiles). An FFG or DDG in company with a commercial spec icebreaker would seem more than a match for them.

Contrary to much of the recent press coverage, we’re nowhere near having armed icebreakers slugging it out in the Arctic.

Shafting/Propulsion:

The NAS report continues:

Application of MIL-SPEC to shafting could significantly limit the availability of alternatives to conventional shafting. Podded propulsion system makers may not have equipment or designs in compliance with MIL-SPEC and may be unwilling to customize their equipment, except at a higher cost. Customizing a propulsion system design can lead to specialized designs that are difficult to service and obtain parts for, which would increase maintenance costs for the life of the vessel. (p. 73)

It seems that the PSC design does not require MIL-SPEC shafting or propulsion.

According to press releases, the PSC design uses two ABB Azipod V3000 pods and one standard propeller. Looking through the Azipod catalog, it seems very likely that these will be Azipod VI (a high-powered variant of the Azipod V designed for icebreakers).

Charcot has two Azipod VI2300L type units rated at 17 MW each. It is possible that a similar model will be installed on the PSC, although probably with a lower power rating4.

It appears that in this category, Charcot and the PSC will meet an equivalent standard.

Diesel Engines:

The NAS report continues:

Diesel engines are likely planned for the new icebreaker. The major worldwide manufacturers of medium-speed diesel engines produce hundreds of engines per year, and these engines have a history of reliable operation and worldwide availability of parts and service. Extensive testing will not make a poorly designed or hard-to-service engine reliable. The key to engine reliability is selection of an engine from a maker with a proven track record. The selection of engine suppliers will be reduced significantly if the new icebreakers are required to have U.S.-built engines that meet MIL-SPEC requirements. The result is likely to be an engine that is less reliable and less easy to maintain. USCG would be better served by procuring the best engines available and not restricting the engines’ country of origin. (p. 73-74)

According to the original press release, Caterpillar was to provide the diesel engines for the PSCs. One small problem, though- in 2021, Caterpillar announced that it was phasing out production of its medium speed diesel engines. From a Maritime Executive report of July 14, 2021:

American engine-builder Caterpillar has decided to phase out production of its medium-speed diesel engines, the company confirmed in a statement. The decision affects manufacturing plants in Kiel, Germany and in China, and employees have been notified. Existing MaK engine owners will still be able to obtain parts and service from Cat.

According to the USCG, this is not a problem. From a January 2022 e-mail from the USCG to the Congressional Research Service:5

Halter Marine, Inc. (HMI) established an agreement with Caterpillar to ensure availability of the combined engine-generator “gen sets” [generator sets] for the three ships in the PSC Program of Record. Caterpillar also provided extended warranties on the gen sets for PSC together with assurances that they are committed to life cycle support of the units. No other aspects of the [PSC] ship design or construction are expected to be impacted by Caterpillar’s decision to cease production of medium-speed marine diesels.”

So where are the PSC’s diesel generators coming from? Germany. According to a DoD announcement of August 12, 2024:

Bollinger Mississippi Shipbuilding, Pascagoula, Mississippi, is awarded a $37,990,331 firm-fixed-price modification to previously awarded contract (N00024-19-C-2210) to exercise an option for provisioned item orders to procure a diesel generator. Work will be performed in Rostock, Germany (90%); Mankato, Minnesota (5%); and Lafayette, Indiana (5%), and is expected to be completed by December 2025. Fiscal 2021 procurement, construction, and improvement (Coast Guard) funds in the amount of $37,990,331 will be obligated at time of award and will not expire at the end of the current fiscal year. Naval Sea Systems Command, Washington, D.C., is the contracting activity.

Caterpillar/MaK builds diesel engines in Rostock. Although arranged through an American company, the diesels will be manufactured overseas.

Considering that Caterpillar/MaK is getting out of the medium-speed diesel business, these are likely some of the last medium-speed diesel engines they will build. Although support is ‘promised’ for the future, selecting an engine type still in production would do more to assure future parts availability.

Since the USCG is acquiring foreign-built diesel engines, perhaps it should consider a manufacturer that builds diesel engines specifically for cold-weather applications and, because of that expertise, is the main provider of diesel engines for icebreakers: Wärtsilä.

Wärtsilä by the numbers:

(Information on icebreaker diesel engines compiled with much assistance from publicly available sources. Thank you for the help!)

If we consider only icebreakers commissioned after January 1980 and exclude those under construction, that adds up to 137 built icebreakers and other icebreaking vessels (excluding cargo ships and tankers).

57 ships were built with Wärtsilä engines and at least one has been re-engined with them. The runner-ups are Bergen (12 ships), Caterpillar (11 ships; excluding MaK), Fairbanks-Morse (8 ships), MAN (6 ships), Alco (5 ships) and MaK (5 ships).

36 of the Wärtsilä-powered icebreakers have Wärtsilä 32 series engines; it is by far the most common single model used in icebreaking ships6.

Canada has selected Wärtsilä 31 series engines for its heavy polar icebreakers.

Additionally, Wärtsilä diesel engines also power 36 ice-capable cargo vessels including the 15 Arc7 LNG carriers built by Hanwha that I wrote about previously.7

Le Commandant Charcot uses Wärtsilä 31 series diesel engines.

If the availability of support and parts is a concern, it would seem that buying Caterpillar/MaK diesels is a less-than-optimal solution compared to a specialty manufacturer such as Wärtsilä.

Communications, Weapons, Proprietary Systems:

For specialized communications, weapons, and other systems exclusive to USN, application of MIL-SPEC would be appropriate to ensure that the equipment meets special mission requirements and is compatible with equipment on other USCG and USN vessels. The equipment to which this applies is limited in nature and much of it is government furnished, so it would not have a significant impact on icebreaker cost. (p. 74)

This is just common sense- as a U.S. Coast Guard vessel, it will need to use MIL-SPEC communications and sensor systems in order to operate with other USCG and U.S. Navy vessels. This also applies to weapons systems, should they be installed. I’m sure that Aiviq will have the required systems added as part of her modification for USCG use.

The PSC design is supposed to reserve power, space, and weight for additional systems, whether they be weapons systems or science research facilities.

NAS Report Conclusion:

The committee believes that the adverse impacts on design, cost, and availability of reliable equipment outweigh any anticipated benefits that application of MIL-SPEC requirements to a new polar icebreaker might provide. The most cost-effective and reliable icebreaker for USCG is likely one that is designed and built to appropriate commercial and international standards for a polar icebreaker, similar to icebreakers in other nations around the world. (p. 74)

Overall Score Card:

I can only infer that the PSC is a partial MIL-SPEC vessel based on the cost and difficulty of design. The planned use of Azipods means that it is not, however, a full MIL-SPEC vessel.

Let’s compare Charcot and the PSC based in four areas used within the NAS report:

Damage Stability and Survivability: Advantage Charcot.

“Overall, the committee anticipates that applying international and polar damage stability requirements will result in a ship that is safer in ice conditions without having to manage the more costly and difficult-to-design changes needed to meet MIL-SPEC requirements for a ship anticipating combat.”

As ice is a more present danger than combat, commercial standards are better suited to regular operations. When accompanied by a U.S. Navy combatant, its survivability (according to OPNAVINST 9070.1B) greatly increases.

Shafting and Propulsion: Tie

Both vessels are using Azipods, perhaps even the same size/model.

Diesel Engines: Advantage Charcot

Charcot’s Wärtsilä diesel engines come from a company specializing in cold weather operation. The PSCs engines are among the last medium-speed diesels being produced by Caterpillar/MaK, and as such may lack future parts support.

Communications, Sensors, and Weapons: Advantage PSC

The PSC will be built with the required MIL-SPEC sensors. Charcot has modern commercial sensors and communications systems but would need to be outfitted with the required MIL-SPEC gear in order to meet USCG standards.

As we are mainly comparing the icebreaking and survivability of the vessels, this category isn’t as relevant as the other three.

My Conclusion:

Based on my reading of all the standards I could find and the comparisons contained in the NAS report, I think that it is fair to say that Charcot and the PSC are built to meet different standards.

Going back to my initial question:

Is an icebreaker built to commercial standards (such as Le Commandant Charcot) actually built to a lower standard (less capable and less survivable) than a partial MIL-SPEC vessel (such as the Polar Security Cutter)?

The answer is a clear NO. The Commercial standards are different, but they are not lesser.

Considering other regulations, standards, and procedures associated with acquiring icebreakers for the U.S. Coast Guard, such as the Federal Acquisition Regulations and the entire budget process, asking whether Charcot will be ‘as good as’ a PSC is the wrong question.

The right question: What benefit do all of these USCG and U.S. Government processes, procedures, and standards provide if they result in a ship that is similar is capability to a commercial vessel, but take years longer and add hundreds of millions of dollars in additional cost?

The NAS recommended building a full commercial standard vessel. Perhaps the next class built for the USCG will follow this route. More on that in a forthcoming update on the PSC program.

Thanks for reading. Please let me know what you think about this comparison. If you like what you’ve seen, press the heart and subscribe to make sure that you never miss an update. Consider sharing with a friend or fifteen; it takes me some time to research and write these articles, so I’m happy to see them spread far and wide. It’s important to keep this conversation going.

Until next time.

All the Best,

PGR

Somewhat confusingly, different words are used by each organization for their requirements. For example, Polar Code refers to itself as a code, with both mandatory provisions and recommendations. The IACS Polar Class has requirements, the classification societies use rules, and the Navy uses criteria, practices, policies, and standards. I’ll do my best to use the proper terms on the commercial side but will follow the NAS practice of using MIL-STD as a shorthand for all of the U.S. government requirements.

This means that in 100% of situations, the ship will survive flooding of all spaces associated with damage to the side of the vessel equal to 4.5% of its length.

Contrary to all of the recent articles, the Project 23550 vessels are PC3 equivalent patrol vessels. They do not meet the additional requirements for icebreakers, and as such are not icebreakers.

According to press releases, the PSC will have 45,200hp- or 33.7 MW of power. It is not clear if that refers to total propulsion power or total diesel-electric power. Assuming total propulsion power, the power per Azipod will be lower as the PSC incorporates a third conventional shaft.

As cited in Coast Guard Polar Security Cutter (Polar Icebreaker) Program: Background and Issues for Congress Updated January 17, 2024, page 27. This section was revised out of later versions of the CRS report.

Complete list of all operational icebreakers with Wärtsilä engines (excluding older license-built engines):

Canada: CCGS Samuel Risley (W22), CCGS Sir Wilfrid Laurier (refit, unknown model), CCGS Henry Larsen (W32)

China: Zhong Shan Da Xue Ji Di (W32), Xue Long (W60; refit), Xue Long 2 (W32), Tan Suo San Hao (W32; under construction)

Finland: Voima (W22; refit), Otso (W32), Kontio (W32), Fennica (W32), Nordica (W32), Louhi (W20), Polaris (W34DF)

France: L'Astrolabe (W20), Le Commandant Charcot (W31DF)

Russia: Ivan Kruzenstern (W26; refit), Semyon Dezhnev (W26; refit), Mikhail Somov (W32; refit), Kapitan M. Izmaylov (W24), Kapitan Kosolapov (W24), Kapitan Chechkin (W22), Kapitan Plakhin (W22), Kapitan Bukaev (W22), Kapitan Chadaev (W22), Kapitan Krutov (W22), Kapitan Zarubin (W22), Magadan (W32), Mudyug (W32), Dikson (W32), Kapitan Babichev (W22), Kapitan Borodkin (W22), Kapitan Chudinov (W22), Kapitan Evdokimov (W22), Avraamiy Zavenyagin (W22), Kapitan Demidov (W22), Kapitan Metsayk (W22), Kapitan Moshkin (W22), Akademik Fedorov (W32), Georgiy Sedov (W26), Antarcticaborg (W26), SCF Sakhalin (W38), Antey (W32), Hermes (W32), Toboy (W32), Moskva (W32), Varandey (W32), Sankt-Peterburg (W32), Akademik Tryoshnikov (W38), Vitus Bering (W32), Aleksey Chirikov (W32), Baltika (W26), Beringov Proliv (W32), Murman (W32), Vladivostok (W32), Murmansk (W32), Novorossiysk (W32), Gennadiy Nevelskoy (W32), Stepan Makarov (W32), Fedor Ushakov (W32), Ilya Muromets (W32), Yevgeny Primakov (W32), Aleksandr Sannikov (W32), Andrey Vilkitsky (W32), Ob (W31), Viktor Chernomyrdin (W32),

South Africa: S. A. Agulhas II (W32)

Sweden: Ale (W24)

Ukraine: Noosfera (W32+W22)

Arctic cargo ships: Norilskiy Nickel (W32), Monchegorsk (W32), Nadezhda (W32), Talnakh (W32), Zapolyarnyy (W32), Enisey (W32)

Arctic shuttle tankers: Vasily Dinkov (W38), Kapitan Gotsky (W38), Timofey Guzhenko (W38), Mikhail Ulyanov (W38), Kirill Lavrov (W38)

Arctic condensate tankers: Boris Sokolov (W32), Yuriy Kuchiev (W32), Anatoly Lamekhov (W32)

Arctic module carriers: Audax (W32), Pugnax (W32)

1st series of Arc7 LNG carriers: Christophe de Margerie + 14 sister ships (W50DF)

2nd series of Arc7 LNG carriers from Zvezda: Aleksey Kosygin +4 sister ships (W50DF)

Extremely comprehensive and informative article. Please keep up the good work!

Thank you for writing this excellent article.

How confident are you that a Constellation-class frigate or a Burke could operate in diminished ice conditions in the wake of an ice breaker?

This article is a little ambiguous, but it indicates that an un-modified Burke would not be able to function in diminished ice.

https://news.usni.org/2019/09/18/arleigh-burke-destroyers-are-most-viable-option-for-near-term-navy-presence-in-arctic#:~:text=The%20amphibious%20assault%20ships%20don,addressing%20limitations%20for%20hull%20structures.